A team of students in the Department of Mechanical, Aerospace, and Biomedical Engineering have spent the last two semesters working with UT’s Forensic Anthropology Center, better known as The Body Farm, to build a bone fracturing device needed for research.

“The device will be used to help document the survivability of blunt force fracture evidence following a burning event, and will provide tools to successfully differentiate blunt force trauma from thermal trauma,” said Research Associate Professor and Assistant Director of The Body Farm Giovanna Vidoli. “This will improve the scientific knowledge of the fracture pattern expected in bone with pre-existing trauma.”

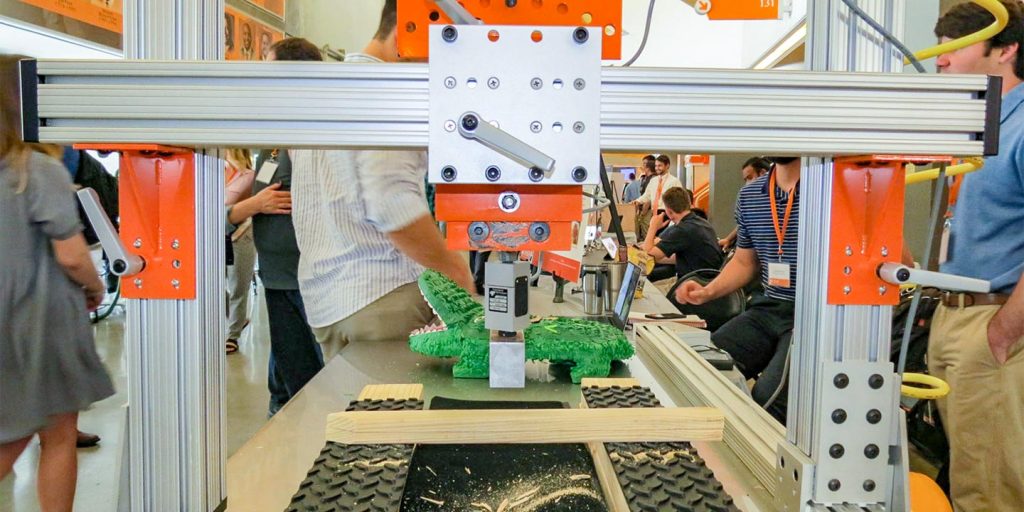

After meeting with Vidoli and her co-researcher, Distinguished Lecturer and Assistant Director Joanne Devlin, and doing some research, seniors Carter Breeding, Daelyn Greene, Nicholas Poker, Ryan Smith, and Zachary Ziegler designed and built a device—which they named the Bone Crusher—that can deliver blunt force impact to bones, and fracture bones.

“Research into many different kinds and sources of trauma was performed in an attempt to find accurate force values,” Greene said. “Data from impact trauma performed in a lab setting, trauma data acquired from car crashes, and trauma data acquired from crime scenes were three of the major sources we used to get an accurate picture of the varying forces we needed to output with the Bone Crusher.”

The Bone Crusher, which is six feet long and six-and-a-half feet tall, allows users to control the amount of force, impact duration, and location of impact on the bones, all of which are needed for the research.

—Giovanna Vidoli

The device was built so the output force is easily adjustable and the impact duration can be adjusted in increments of 0.1 seconds. The largest force the students recorded during their testing was 1,900 pounds.

The students built the device for their senior design course, which allows students to apply all their acquired knowledge and skills in engineering and science to solve an actual problem within the community.

“The most enjoyable part of this project was being given free rein to conceptualize, design, and build a prototype using the fundamentals we have been learning in classes leading up to the senior year,” Breeding said. “The fabrication stage was by far my favorite, because I enjoy being hands-on and building things.”

The final prototype was displayed at the Tickle College of Engineering’s Senior Design Showcase and gained the team the First Place Best Mechanical Engineering Project Award.

The faculty and students at The Body Farm plan to start using the device on human bodies in the fall.